Cable types :

| JUS | GOST | DIN | |

| TO SM 03 (04) | OKK-10-01 | A-DF(ZN)2Y mxnE...F...LG | nonmetalic |

| TO SM 19 | OK3B'-10-02 | A-DF(L)(ZN)2YN2Y mxnE...F...LG | armoured |

| TO SM 09 | OKK-10-02 | A-DF(L)(ZN)2Y mxnE...F...LG | duct |

| TO SM 31 | OKP-10-02 | A-DF(ZN)(L)(TR)2Y mxnE...F...LG | self-supporting |

Transmitted characteristics of optical fibres in cable

The characteristics of monomode (SM) and multimode (MM) optical fibres for LAN and CATV telecomunication networks are given in the following Tables :

T 1.Step- index monomode optical fibre(Mached Cladding)

a./ OPTICAL CHARACTERISTICS

| Optical attenuation max. value (dB/km ) category : | ||

| A | B | |

| range 1300 do 1310 nm | 0,40 | 0,50 |

| at 1550 nm | 0,25 | 0,30 |

| Dispersion max. value ( pS/nm.km): | ||

| range 1300 do 1310 nm | 3,50 pS/nm.Km | |

| at 1550 nm | 20,0 pS/nm.Km | |

| Mode diameter field, nom. microns | 9 do 10 +/- 10% | |

| Cutt-off wavelength , nm : | 1100 do 1280 nm | |

b./ Geometrical characteristics

| Optical cladding diameter (microns) | 125 (+/- 2) |

| Cladding ovallity error , max. | 2 % |

| concentricyti error max. | 1,0 micron |

| Acrylate double layers primary coating,diameter: | 250 (+/- 15) microns |

c./ Mechanical characteristics :

| Skrin test ( 1s ) min. vrednost: | 1 % |

Additional attennuation due to the macro bending :

(100 turns 0n 60 mm mandrel diameter)

| at 1300 nm | 0,05 dB max. |

| At 1550 nm | 0,10 dB max. |

The characteristics of SM optical fibres are in according with CCITT Rec. G.652

Besides monomode optocal fibres in the broadband networks it can be expected the application of graded index multimode optical fibres specially in the cases when there is a desire to the price reduction of theterminal units and when it is necessary to realize biger number of the connections wher multimode optical fibres have the adventage because of biger diameter of core.Multimode optical fibres have more and more application for LAN network and because of that it is alleged multimode optical fibres characteristics with 50 and 62.5 core diameter that there is in international standard requirements as standard. T 2.Graded index multimode optical fibres of 50 and 62.5 microns .

Graded index multimode fibre 50/125/ 62.5/.

a./Optical characteristics :

| Optical attenuation : | |||

| at | 850 nm max. | 2,50 dB/Km | 3,50 dB/Km |

| at | 1300 nm max. | 0,70 dB/Km | 1,20 dB/Km |

| Bandwidth (MHz.Km): | |||

| At | 850 nm min. ( MHz.Km ) | 400 | 200 |

| At | 1300 nm min. ( MHz.Km ) | 600 | 500 |

| Numerical aperture : | 0,20 (+/- 0,02 ) | 0,275(+/- 0,015) | |

b./ Geometrical characteristics :

| Fiber core diameter , micron | 50 ( +/- 3 ) | 62,5 (+/- 3) | ||

| Optical cladding diameter , micron, | 125 (+/- 2 ) | 125 (+/- 2 ) | ||

| Primary coating diameter , microns | 250 (+/- 10) | |||

c./ Mechanical characteristics :

| Screen test , min. ( 1S). | 5 % |

Optical cable construction :

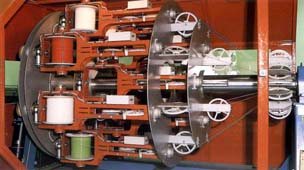

The construction basic elements of non-metallic optical cable forseen for duct pulling are shown on figure 1.

Sl. 1.

Optical cable core constitute :strain relief element, optical fibres laid iside secondary coating loos, filling compound and belt isolation with the strain relief elements .Central strain relief element can be made by high tensile strength galvanized steel wire or for non- metallic optical cables by glass roving epoxy/poliester impregnired .Central element diameter of the cable is in compliance with deemands of cable mechanical characteristics. Secondary coating tubes contain up to 6 optical fibres that distinguished each other according to primary coating colour . Dimensions of looses are:2.0/1.2mm(+/- 0.05 mmm , outher/ inner loos diameter ) for construction with one or two optical fibres in the same secondary coating loos. 2.8/ 1.7 mm(+/- 0.06 mm, outher/inner loos diameter) for construction with four or six optical fibres in the same secondary coating loos.

NON- METALLIC OPTICAL CABLES FOR BLOW-IN PLASTIC TUBES TO SM 03 (or 04)

Optical cables of type TO SM 03... and TO SM 04... are made without metallic elements , forseen for blow-in tubes without puuling. As supporing elements it can be used aramide fibres and epoxy/plastic strain relief element. Cables are with loos tube secondary coatin with interstices filled with waterproof compound.Cable can be with polyethylene (03) or PVC(04) jacket.

Main technical characteristics for non-metallic optical cables :

| -Attenuation coefficient max. value dB/Km , category : | A | B | |

| at 1300nm | 0,40 | 0,50 | |

| at 1550nm | 0,25 | 0,30 | |

| Temperature range : | |||

| exploatation | - 300 C do + 700 C | ||

| installation | - 50 C do + 50 0 C | ||

| Minimal bending radius : | 20 x cable diameter | ||

| Maximum tensile load: | 1550 N | ||

| Number of optical fibers in cable | Cable diameter, max mm |

Cable mass (app) Kg/Km |

| 4, 6, 8, 10 i 12 | 11,40 | 103 |

| 16 | 12,90 | 120 |

| 18 i 20 | 14,0 | 145 |

| 22 i 24 | 14,0 | 144 |

| 26,28 i 32 | 15,70 | 175 |

| 36 i 40 | 17,50 | 215 |

| 44 i 48 | 19,10 | 262 |

Armored optical cables for direct burial TO SM 19 P...

Optical cables of type TO SM 19 P... are made with the steel tapes armour, foreseen for direct burial into ground. For supporting elements it can be ferseen aramide fiber and strain relief element of galwanized steel wire (or glass/plastic). Cables are made with looos tube secondary coating and filled with waterproof compound inside interstices.

Main technical caracteristics armoured optical cables :

| Attenuation coefficient max. dB/Km , category : | A | B | |

| At 1300nm | 0,40 | 0,50 | |

| At 1550nm | 0,25 | 0,30 | |

| Temperature range cables application: | |||

| exploatation | - 300 C do + 700 C | ||

| instalation | - 50 C do + 50 0 C | ||

| Min. bending radius : | 20 x cable diameter | ||

| Max. tensile load | 2200 N. | ||

| Number of optical fibres in cable | Cable diameter, max. mm |

Cable mass (app) kg/km |

| 4, 6, 8, 10 i 12 | 16,50 | 345 |

| 16 | 14.10 | 405 |

| 18 i 20 | 15,80 | 426 |

| 22 i 24 | 16,90 | 480 |

| 26,28 i 32 | 15,90 | 430 |

| 36 i 40 | 17,60 | 475 |

| 44 i 48 | 18,80 | 485 |

DUCT OPTICAL CABLES FOR DUCT PULLING TO SM 09 P...

Optical cable of type TO SM 09 P... are made with laminated sheath of aluminium tape 0.2 mm thickness,covered with polyethylene copolymer sticked to polyethylele sheath.forseen for pulling into cable duct . As supporting elements it can be used aramide fiber and strain relief element of galvanised steel wire (or glass/plastic).Cable are desined by loose tube secondary coating and filled with waterproof compound insides interstices. Main technical characteristics :

| Attenuation coefficient , max. dB/Km , category: | A | B | |

| at 1300nm | 0,40 | 0,50 | |

| at 1550nm | 0,25 | 0,30 | |

| Temper. range | |||

| exploatation | - 300 C do + 700 C | ||

| instalation | - 50 C do + 50 0 C | ||

| Min. bending radius : | 20 x cable diameter | ||

| Max. tensile load : | 1600 N | ||

| Number of optical fibres in cable | cable diameter, max mm |

Cable mass (app) Kg/Km |

| 4, 6, 8, 10 i 12 | 12,70 | 115 |

| 16 | 13,80 | 158 |

| 18 i 20 | 15,20 | 180 |

| 22 i 24 | 16,20 | 205 |

| 26,28 i 32 | 14,00 | 165 |

| 36 i 40 | 15,10 | 185 |

| 44 i 48 | 16,30 | 210 |

SELF-SUPPORTING OPTICAL CABLES TO SM 31 P...

Optical cables of type TO SM 31 P... are made with laminated sheath of aluminium tape 0.2 mm thickness, covered with polyethylene copolymer sticked to polyethylene sheath, forseen for installation on overground posts for the span of 50 m nom. Central strain relief element of the cable is desined from glass/plastic (or from galvanised steel wire).Cables are made with loose tube secondary coating and filled with waterproof compound inside interstices. Supporting strand of the cable sonsists of galvanised steel wire 3.00 mm diameter nom. Main technical characteristics :

| Attenuation coefficient , max. dB/Km , category: | B | |

| at 1300nm | 0,50 | |

| at 1550nm | 0,30 | |

| Temperature range: | ||

| exploatation | - 300 C do + 700 C | |

| installation | - 50 C do + 50 0 C | |

| Minimal bending radius : | 20 x cable diameter | |

| Max. tensile load : | 3600 N | |

| Self-supporting cable mass for the constructions up to 12 optical fibres is | app. 198 Kg/km | |

| Outher cables dimension(up to 12 optical fibres) : | 12,70x20,10mm | |